PRINTING PROTECTION

ECU team works to make safety equipment for medical professionals

A group of East Carolina University students has teamed up with faculty and administrators from various departments in hopes of providing needed safety equipment to medical personnel.

With concerns over possible shortages of masks and face shields to protect against COVID-19, the team is working to develop such equipment through the use of three-dimensional printers in ECU’s Innovation Design Lab (IDL).

Student Sarah March tries on one of the face shields. (Photo submitted by Sarah March)

Wayne Godwin, director of the IDL, said the team is using models of masks and shields that are available online and making design modifications based on suggestions from ECU medical professionals.

“During this national emergency, the number of personal protective equipment (PPE) available to medical professionals is projected to be at a critical shortage,” Godwin said. “The medical community is the first line of defense for our region. If we lose our medical professionals because they are ill and can’t come to work, it will result in the people in the region who need help having no place to receive it.”

The 3D printer constructs a mask in 1,425 layers in about three hours. Godwin said the team is attempting to tweak the procedure to reduce the print time. The team has about 20 printers available for production.

Godwin said the team is working well, despite being together for only a couple weeks and working remotely or in small groups of three to four people.

“We design, build, test and learn,” Godwin said. “ … Right now, all we can do is try. We prototype and hope it will be helpful to our medical professionals. No one has been in this situation before, so we are genuinely wayfinding as a team.”

The team includes more than 30 faculty members and professionals in consultation with everyone from state officials to Marines at Camp Lejeune. Godwin said he finds true inspiration from the students involved in the project.

“We have our ‘most excellent’ resource, student interns, who want to help in any way that they can,” Godwin said. “They have worked tirelessly on this wicked problem, and they stand ready to work until we find a solution for all. … The students are leading the charge and taking ownership of what we are doing in the Honors College Innovation Design Lab. I learn from them daily and am inspired by what I believe is a bright future for our nation.”

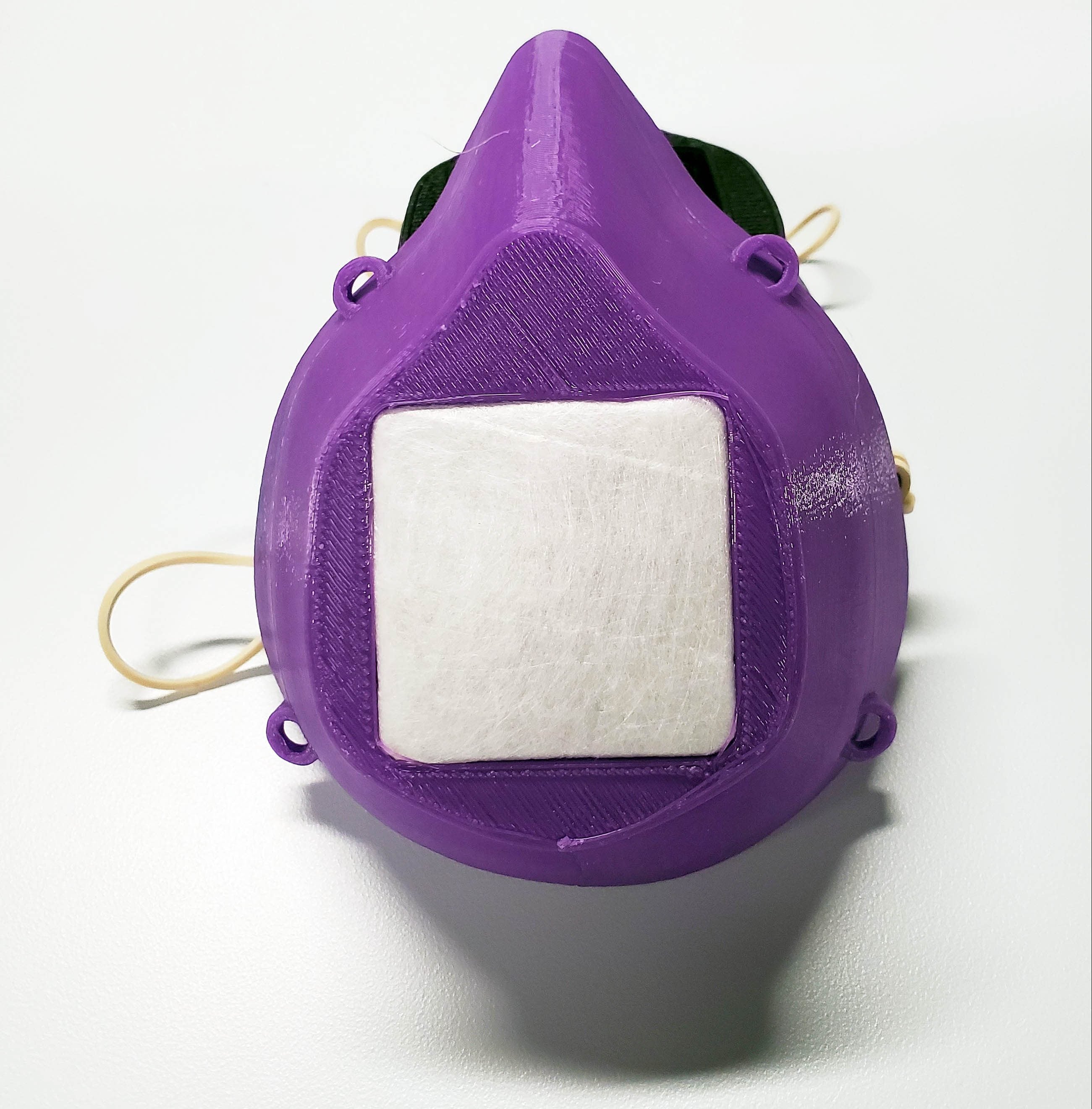

A sample of one of the 3D printed masks. (Photo submitted by Wayne Godwin)

Sarah March, a sophomore biochemistry major and Honors College student, is one of the students involved in the effort.

“I first got involved after being inspired by a lot of similar projects all over the nation and world,” said March, whose father Dr. Juan March is an emergency physician at Vidant Medical Center in Greenville and professor at the Brody School of Medicine.

She said the most difficult part of the project is to make the masks and shields comfortable for those wearing them.

“A lot of people don’t think about it, but when the worst of COVID-19 hits, medical providers will be wearing their PPE for up to 12 hours straight,” March said. “This is a problem we’re hoping to overcome with our next round of prototypes, by adding or changing the materials we use to make the masks. One of our ideas includes lining the edges of the masks with more comfortable material, like liquid rubber.”

She credited those students working directly with the 3D printers for their efforts.

“Their work with the 3D printers is amazing, to say the least,” March said.

March said she hopes the masks and shields the team is designing never have to be used. She said the team wants everyone to take the necessary steps to prevent the spread of the virus, thus reducing the need for any extra equipment for the medical professionals.

“I just want to express how thankful I am to be a student at a university that supports their community,” March said. “Our group is comprised of undergraduate students, medical students, professors, emergency physicians, trauma surgeons, and directors and deans of different departments at ECU. It is truly amazing to have a university with students and faculty that are tightly interwoven within the community.”

Dr. Mark Stacy, ECU’s vice chancellor for health sciences and dean of the Brody School of Medicine, appreciates the effort.

“It is heartening to know that the ECU community is pooling its talents, knowledge and resources to explore solutions to some of the most pressing problems emerging from this health crisis,” Stacy said. “That their efforts could potentially aid our health care providers on the front lines highlights the collaborative spirit that our university is known for — a spirit of service that calls upon creativity, initiative and interprofessional collaboration among our scholars when it matters most.”

The Innovation Design Lab has multiple printers available to make masks and shields. (Photo submitted by Wayne Godwin)