BREATHING EASY

ECU research aims to minimize summer misery for outdoor workers

Summer months in eastern North Carolina mean hot, sticky days with heat indexes that can take the breath away, particularly for those who work outdoors. Add to that a respirator mask worn for job safety and misery levels soar into dangerous territory.

Research at East Carolina University aims to minimize discomfort for outdoor workers, while increasing their compliance with workplace safety requirements, through design of a lighter, thinner and more efficient respirator mask.

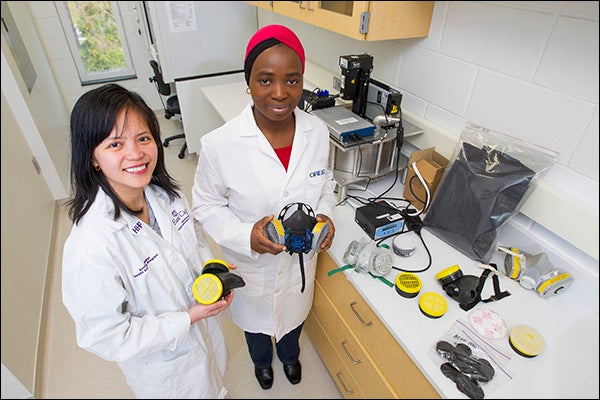

Dr. JoAnne Balanay, assistant professor in the Department of Health Education and Promotion, is conducting the research in collaboration with the University of Alabama, aided by a $20,000 research grant from the National Institute for Occupational Safety and Health.

“Wearing respirators against airborne pollutants is important for worker protection,” Balanay said. The correct respirator can keep workers from inhaling dangerous substances and reduce their risk of developing exposure-related diseases.

According to the United States Department of Labor, 5 million workers are required to wear respirators in more than 1 million workplaces throughout the country. But worker compliance with respirator requirements drops in the summer when temperatures rise.

“It is not easy to wear tight-fitting respirators for prolonged periods because it can be uncomfortable, especially in the hot and humid conditions of eastern North Carolina,” Balanay said.

“In addition to the burden on the lungs caused by breathing resistance through the respirator, extra discomfort is caused by heat buildup within the tight-fitting facepiece,” which increases facial sweating, she said.

Balanay is aiming to resolve the problem by evaluating designs of respirator cartridges and filters made of activated carbon fibers. Her research assesses the designs against airborne toluene vapors, a risk for workers in manufacturing, automotive body repair, construction and janitorial processes. Toluene is a volatile chemical found in paint, cleaning agents, adhesives and ink. It may be used to manufacture nylon, plastic soda bottles and dye.

Balanay’s previous research identified activated carbon fibers as a good alternative to the standard granular activated carbon used in gas and vapor respirators currently on the market. The fabric form of carbon fibers is easier to handle and has a higher absorption capacity. Those features have the potential to significantly decrease the weight and thickness of respirators, while at the same time increase protection against exposure to dangerous chemicals.

ECU environmental health graduate student Adepeju Adesina assists in the lab. She tests combinations of cloth and felt materials made of the activated carbon to determine which respirator cartridge and filter designs allow workers to breathe most comfortably.

“Our research is aimed at designing efficient and comfortable respirators that meet NIOSH requirements,” she said. NIOSH is the National Institute for Occupational Safety and Health, which works to reduce workplace hazards.

Phil Lewis, assistant director of the ECU Office of Environmental Health and Safety, said the research could prove beneficial to workers. “Wearing a respirator while working for several hours can be uncomfortable, awkward and hot,” he said, but the thinner design “would encourage workers to use their respirator.”

Dr. Glen Gilbert agreed. Gilbert is dean of the College of Health and Human Performance, where the Department of Health Education and Promotion is housed. He said the research is “critical to the public health of eastern North Carolina.”

“If we can make it comfortable for workers to use respirators, it will pay great dividends in reduced health care costs down the road and greatly improve the quality of life for the users,” Gilbert said.