CELLINK demonstrates 3D bioprinter

Students and faculty in East Carolina University’s College of Engineering and Technology had the chance to see and discuss the operation of a 3D bioprinter, technology that could lead to the printing of viable human organs.

Dr. Barbara Muller-Borer, chair of the Department of Engineering, said the possibilities of the technology are fascinating. She pointed to the research of Dr. Anthony Atala, who has used a similar process to print a prototype of a kidney at Wake Forest University.

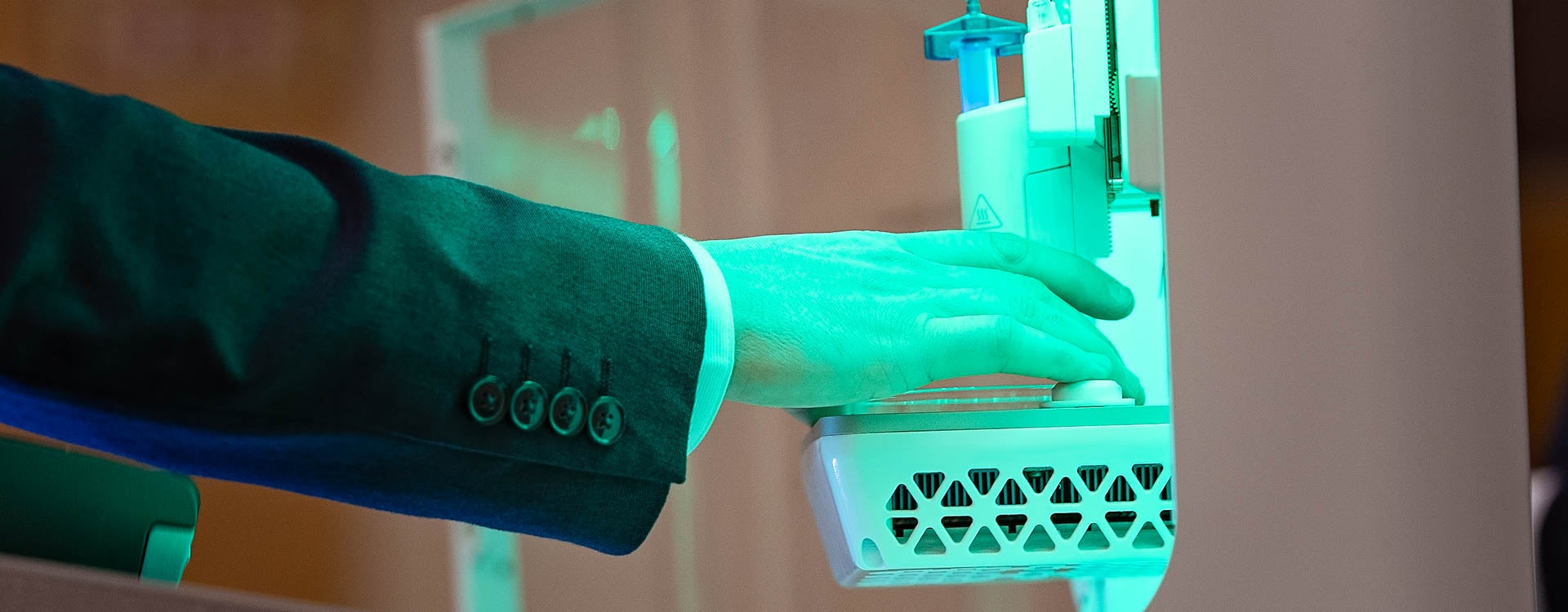

Representatives from CELLINK demonstrated the use of a 3D bioprinter for students and faculty in the College of Engineering and Technology. (Photos by Cliff Hollis)

The CELLINK Bio X is a standalone 3D bioprinter that is designed for user friendliness, allowing the possibility of hands-on student use. It looks and operated much like a normal 3D printer but uses soft materials and cells instead of plastic.

“It was neat to see how simple it is to use and how easy it would be to integrate with our other 3D printing systems, and let the students learn about this technology,” she said.

Daniel Lidberg, CELLINK Nordic sales director, along with Zack Graham, sales executive, pulled the printer out of the box and set it up for printing within a few minutes. The device can be interfaced with a computer or operated directly from the integrated touchscreen.

Lidberg said he’s eager to spread the word about bioprinting and the newest advances and equipment in the field.

“Since it’s a new technology, not a lot of people have been doing it,” he said. “More and more need to do it to move the research further.”

Labs around the world are using 3D bioprinters in rapidly advancing ways, he said. Structures printed with biocompatible materials can be infused with living cell cultures that can then grow and survive for weeks.

“What we can do today is to minimize animal testing by printing a 3D cell culture (that can be used in research),” he said. “What we can’t do today is print a full organ, but we can print a soft tissue model.”

Dr. Ranjeet Agarwala, assistant professor of technology systems, examines a scaled model of a human ear printed by the device.

For the demonstration, Lidberg and Graham printed a model of an ear at 35-percent scale, which took only a few minutes. Lidberg said that printing an organ like skin could be possible within a few years, while denser and more complex organs will take longer.

“We’ve only reached the tip of the iceberg at this point,” Graham said.

Muller-Borer said she was interested in how the device could be used to teach students about the newest in biomedical technology.

“This is where a lot of personalized medicine is going now,” she said. “From a teaching standpoint, if you wanted to have students use it, how student-proof is it? … The touch screen looks like it’s easy to use; it’s easy to clean.”

Tomorrow’s students may print organs as easily as today’s students print a model of the cupola, she said.

https://www.youtube.com/watch?v=N5Ia6qakPDY

-by Jules Norwood, ECU News Services