A PRINTOUT FOR PROGRESS

Grant funds workforce-development program, 3D printer lab at ECU

East Carolina University today opened a new 3D design and prototyping center and announced the start of a workforce-development program that strengthens students’ skills and promotes economic development.

Funded in part by a $300,000 grant from the Duke Energy Foundation through the ECU Office of Innovation and Economic Development, the workforce-development program will offer short courses, workforce certificates and hands-on industry projects through the Integrated Innovation Workforce and Economic Development Initiative.

The grant is part of the Duke Energy Foundation’s $2 million investment in workforce development with six University of North Carolina-system schools. The program is aimed at pharmaceutical and other advanced manufacturing industries.

Left to right, Anna Humphrey of E.B. Aycock, Mark Phillips of the North Carolina Biotechnology Center and E.B. Aycock student Jack Vick demonstrate their work at ECU’s new lab.

Called the ECU Innovation Design Lab, the 5,600-square-foot facility is in part of the former Overton’s grocery store on Jarvis Street in Greenville. The lab features a new MakerBot Innovation Center for 3D design and prototyping, one of only three in the Southeast and the first in North Carolina.

“The goal of this initiative is to address the documented and increasing demand for formally trained innovators in high-skill, high-pay pharmaceutical and other advanced manufacturing careers throughout the region,” said Ted Morris, associate vice chancellor for innovation and economic development at ECU.

Additionally, the program lays the “last mile” of an education-to-workforce pipeline connecting eastern North Carolina middle- and high-school students to career opportunities via the Golden Leaf Advanced Manufacturing and Innovation Academy.

“East Carolina University is committed to equipping its students with the skills needed to compete in emerging sectors of today’s economy,” said David Fountain, Duke Energy’s North Carolina president. “We’re excited to make this important investment in eastern North Carolina and to work with the university to strengthen the region’s education-to-workforce pipeline.”

Together, these programs increase students’ awareness of regional advanced manufacturing careers while boosting their science, technology, engineering, art/design, mathematics, innovation, entrepreneurship and leadership skills.

Vice Chancellor Ted Morris, speaking, shows off a wall of new MakerBot 3D printers to ECU faculty member Rick Smiley, left, and ECU College of Business Dean Stan Eakins at the new ECU Innovation Design Lab.

ECU Provost Ron Mitchelson said the MakerBot lab will put students from business, art, science, engineering, medicine and other fields together with industry experts to turn ideas into tangible products.

“As far as I’m concerned, innovation is not a choice. It’s an imperative,” he said. “This kind of facility is right at the base of this imperative.”

3D printing, known in engineering circles as additive manufacturing, uses technology similar to that used in inkjet printers to build products layer-by-layer using plastic or other materials with similar properties. Industrial 3D printers can also use metals, and some are now using biological materials to create human tissue.

While the machines at the lab printed novelty items such as chess pieces, their capabilities and utility go much deeper. David Baines, a project manager with MakerBot, said the technology allows users from individual inventors to major manufacturers to quickly and inexpensively create product prototypes for testing and design refinement.

“It lowers the consequences so they can be creative,” he said. “It’s a couple of bucks instead of thousands.”

He added that MakerBots are built in the company’s factory by other MakerBot machines.

There are similar MakerBot facilities at the University of Maryland and Florida Polytechnic Institute.

The Innovation Design Lab also features space for ECU’s advanced visualization and performance facility, a simulation-based and immersive training environment serving North Carolina’s film and gaming industries as well as the military.

The MakerBot center and simulation facility are separated by a design studio where students can gather to develop, share and improve ideas, projects or products.

Ultimately, ECU’s Innovation Design Lab is intended to increase collaboration and innovation and support the growth of the East Carolina Research and Innovation Campus.

Based in New York City, MakerBot Industries was founded in 2009 to engineer and produce 3D printers. In 2013, Minnesota-based 3D printer and production-system manufacturer Stratasys acquired MakerBot.

In addition to being part of the Innovation Design Lab, the project is a component of ECU’s Pharmaceutical Development and Manufacturing Center of Excellence, which will be a premier laboratory-based education center for preparing pharmaceutical manufacturing and pharmaceutics professionals.

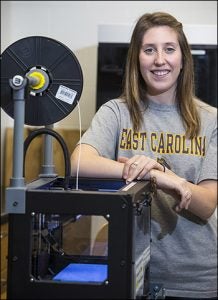

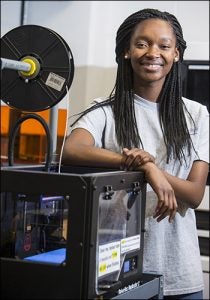

ECU engineering students Amber Lyerly, above, and Angel Chukwu use 3-D printing as part of their education.

ECU engineering students Amber Lyerly, above, and Angel Chukwu use 3-D printing as part of their education.

3D printing merges art, engineering

Amber Lyerly’s tablet plays a video of a water pump she designed and built submerged in a tank spewing water like any heavy-duty industrial machine would.

But in her hand is the same pump, made of plastic in a few hours using a 3D printer in the Science and Technology Building at East Carolina University.

“You can make anything and test anything,” the senior mechanical engineering major said of 3D printing, known more precisely as additive manufacturing. And she’s taken her pump with her to interviews for internships and jobs, and landed an internship last summer at Hayward Pools.

“A lot of jobs I’ve been applying for, they want additive-manufacturing experience,” she said.

The opening of a new MakerBot 3D design and prototyping facility at ECU is a tangible sign the technology is a valuable educational tool.

“It’s a magnet for middle- and high-school kids,” said Ed Howard, associate professor of engineering at ECU.

Ira Varney, an art teacher at South Central High School in Winterville whose classes include 3D printing and computerized machining, was at the opening of the ECU MakerBot lab. He said technologies such as 3D printing get students interested in design, manufacturing and engineering, showing them they can have a career that challenges and rewards their creativity.

“They can find their pathways better,” Varney said. “It’s fun. That’s the kind of job you want, so you never work a day in your life.”

ECU sophomore mechanical engineering student Angel Chukwu of Clayton, a member of the ECU Honors College, described her major the same way.

“It’s like putting art and science together, and it’s fun,” she said.

Lyerly also said the chance that students from various disciplines might work together on 3D-printed products – one way the new MakerBot lab is envisioned to work – is enticing.

“If engineering and the business majors would come together and do a capstone project, I think some really cool stuff would come out of it,” she said.

Pictured above enjoying the ribbon cutting ceremony for the new lab are, left to right, T.D. Goodwin employee Dan Kallweit; Tommy Goodwin; ECU Vice Chancellor of Administration and Finance Rick Niswander; ECU Provost Ron Mitchelson, Wayne Godwin, ECU art professor and director of the innovation design lab; Charles Overton; Ted Morris, ECU associate vice chancellor for engagement, innovation and development; Parker Overton; David Fountain and Millie Chalk of Duke Energy.