AERODYNAMICS LIVE

ECU wind tunnel enables visualization of engineering concepts

Seeing the impact of air and speed on objects beats reading a description in a textbook, according to East Carolina University engineering students.

The principles of aerodynamics come to life in the College of Engineering and Technology’s wind tunnel, which has been in place about a year in the corner of a cargo bay in the Science and Technology Building.

With wind speeds reaching up to 150 mph, the 15-feet long and 6-feet high tube-shaped apparatus has a small compartment to test concepts like drag, lift and momentum caused by air flowing over objects.

Working with objects in the wind tunnel helps students understand more clearly some of the concepts they are learning in the classroom, according to ECU assistant professor Dr. Eban Bean.

“These topics can be very complex, and before (we acquired) the wind tunnel, student interactions with these principles were limited to a conceptual understanding of the forces and equations we use,” said Dr. Eban Bean, ECU assistant professor of engineering.

“Now they can see, feel and understand first-hand how air flow occurs over wings, vehicles and different shapes. This opens up options for our students to really ‘get it.’”

About 75 to 100 engineering and technology systems students use the wind tunnel each semester, using sensors and controls to conduct experiments. Real-time data is captured, monitored, displayed and interfaced with ECU’s computer network for students to access in future experiments.

Some of the products tested in the tunnel are designed and created by students using the college’s 3D printers and rapid prototyping machines. With a smoke generator, students can actually see the aerodynamics on an object in the rectangular-shaped compartment.

“The wind tunnel gives the engineering department a hands-on tool to demonstrate those concepts and allow the students to see the forces and reactions involved in a fluid environment,” said Jeff Foeller, teaching instructor in engineering. “It also gives us the ability to research certain wind-related projects like a human-powered vehicle … or the wing ice buildup that affects commercial planes.”

Students were excited to learn ECU was getting the wind tunnel last year, said Tyler Martin, an ECU senior majoring in mechanical engineering and applied physics. He was there when the machine was installed and tested the first time.

Martin and fellow student Kevin Nicolle used the wind tunnel in their research on human-powered vehicles. “The wind tunnel gave us the perfect platform to test miniature versions of our models and extrapolate the data,” Martin said. “It was a great testing ground for our hypothesis.”

The students built a human-powered vehicle for an annual American Society of Mechanical Engineers competition, entering it in several events, including a drag race, endurance race and design competition.

Future engineers are constantly looking for ways to gain hands-on experience that can help them when they join the workforce, Martin said.

“I fully see the wind tunnel becoming a vital piece of equipment in our curriculum due in part to our fluid mechanics course,” Martin said. “I see the wind tunnel being used extensively by undergraduate researchers who want to expand their knowledge through this piece of equipment.”

Recent graduate John Pope, who now works at Hitachi Automobile in Lexington, Kentucky as a production engineer, used the wind tunnel for an undergraduate research project studying the effects of ice buildup on airfoils, which are a cross section of an airplane wing or blade. He used 3D printing technology to produce scale models of iced and clean airfoils to test in the wind tunnel.

Previous students would have conducted research using computer simulations.

Having the wind tunnel was an advantage, Pope said.

“The wind tunnel connects the classroom to the real world,” he said. “It gives students experience with fluid mechanics and provides the opportunity to see first-hand many of the concepts discussed in class. It also introduces students to some of the more technical details of conducting research or studies that they may encounter in their careers.”

Dr. Hayden Griffin, professor and chair of the ECU Department of Engineering, said the wind tunnel will be even more beneficial in the future “as we increase our activities in autonomous aircraft, which is becoming an important part of our research and development work.”

-Margaret Turner contributed to this story.

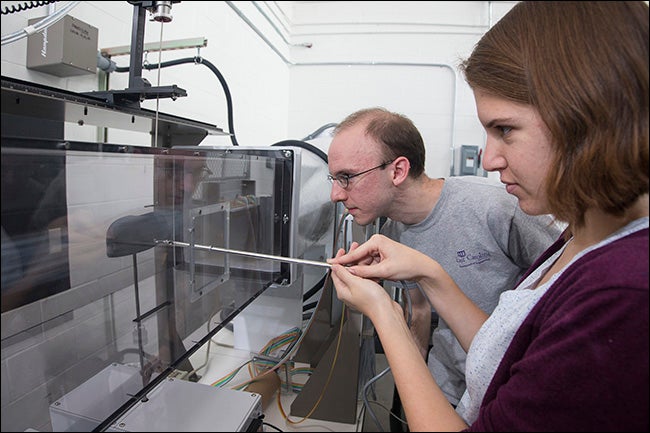

Working with the wind tunnel are engineering students Nicholas Garcia and Carrie Robinson.