INNOVATORS IN ACTION

Academy introduces advanced manufacturing concepts, careers

Rising seventh-grader Alyssa Mayo had never built a robot much less programmed one to move, turn and scoop up a ping pong ball.

But she and 40 other middle school students in Pitt, Beaufort and Edgecombe counties had the opportunity at the first Advanced Manufacturing and Innovation Academy held at East Carolina University June 15-26.

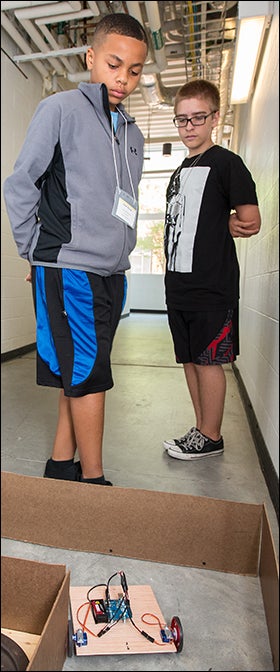

Middle schoolers at the Manufacturing and Innovation Academy at ECU watch as a robot makes its way through a maze.

Hands-on activities engaged students like Alyssa while introducing them to science and technology careers and advanced manufacturing concepts that they might not have considered before.

Funded through a $1.25 million Golden LEAF Foundation grant, the academy is part of a larger initiative that opened pilot entrepreneurship, science, technology, engineering, art and design and math or eSTEAM labs in four middle schools last year. More labs will open this fall with the goal to provide an effective education-to-workforce pipeline to address the growing shortage of eastern North Carolina advanced manufacturing workers and entrepreneurs.

Approximately 40 teachers worked side by side with middle school students in the ECU College of Engineering and Technology to assemble and program a robot to navigate through a maze. “How they will do that? We didn’t plant the seeds. It’s up to them,” said Teresa Ryan, assistant professor of engineering.

Alyssa, who attends Bethel School, connected the wires and battery holder and attached wheels to a robot that she helped build with Daeshawn Smith, a rising seventh-grader at Ayden Middle School, and Shelley Tripp, a seventh and eighth-grade science teacher at Bethel School.

They named their robot “Tadbot,” which was moving well on test runs through the maze.

The final races happened on June 26, the last day of the academy, when teams of two to four took turns sending robots through a walled, U-shaped course to be scored on three things: time, completion and picking up a ping pong ball about midway through and carrying it to the finish. The objective was for the winning robot to autonomously navigate the maze from the start line to the finish line in the shortest amount of time.

“This is all totally new (to me) but all of the people here are here to help,” Alyssa said. “The robots have been my favorite part of the camp.”

Tripp, an ECU alumna, said her school is scheduled to get an eSTEAM lab in the fall. “We’re just trying to expose the kids to more hands-on and future work-ready careers,” Tripp said. “They get to interact with kids from other schools and they get to work with something they don’t usually work with.”

She said it was her first time writing code too. Participants were using Arduino, an easy-to-use and accessible system, to program the robots, Ryan said.

“Sometimes the students are diving in and really engaging in it, or sometimes it’s been the other way around,” Ryan said. “It’s been a good balance on the instructional side.”

Jason Wade, a teacher at Ayden Middle School, said students enjoy the collaboration and unique activities that his school’s eSTEAM lab provides. “It’s totally different than any class they’re taking.”

Christina Leach, a rising eighth-grader at G.R. Whitfield Elementary School, creates a display stand to showcase the prototype of an application she developed to prevent cyber bullying. (Photo by Dee Harper)

Another outcome of the academy, organizers hoped, was to erase the concept of manufacturing as a dirty, greasy occupation. “We’re showing them it’s not necessarily how it is,” Ryan said.

Participants learned how robotics and 3-D printing ties into advanced manufacturing production and saw concepts in practice by touring Greenville’s NACCO Materials Handling Group, which makes industrial lift trucks.

Half of each academy day was spent at ECU’s Willis Building, where students and teachers worked on design and entrepreneurship aimed at moving products to market. There they learned how to translate design, problem solve and communicate the value of their ideas, said Wayne Godwin, director of the innovation design lab and associate professor of art at ECU.

“Introducing students and teachers to eSTEAM concepts and the principals of integrated innovation allows them to develop new ideas and deliver viable 21st century solutions,” Godwin said.

An innovation showcase will be held July 10 in the Willis Building.

Keihin Carolina Systems Technology, a leader in the advanced manufacturing electronics industry based in Tarboro, provided lunches for participants each day.

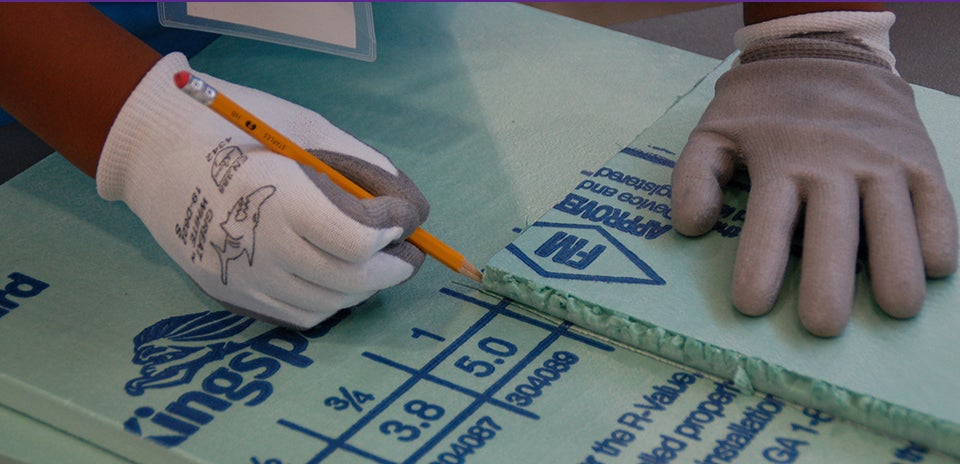

A student at the academy cuts blue foam to create a prototype of his innovation. (Photo by Dee Harper)