DOLLARS AND SENSE

ECU grad students save companies money through class projects

Class projects completed by graduate students enrolled at East Carolina University will save two North Carolina-based companies more than $1 million over the next decade.

Graduate students Brittany Ryan and Robert Johnson completed their projects while earning the Lean Six-Sigma Black Belt certification. The program is designed to equip students with the methodologies of Lean and Six-Sigma, which focus on streamlining industrial and business processes.

At ECU, completion of an industrial or business process project is a requirement of the course.The project must show certified savings or revenue increase.

The idea of students applying things from class and using them in real-world settings is the goal,” Dr. David White, dean of the College of Technology and Computer Science said.

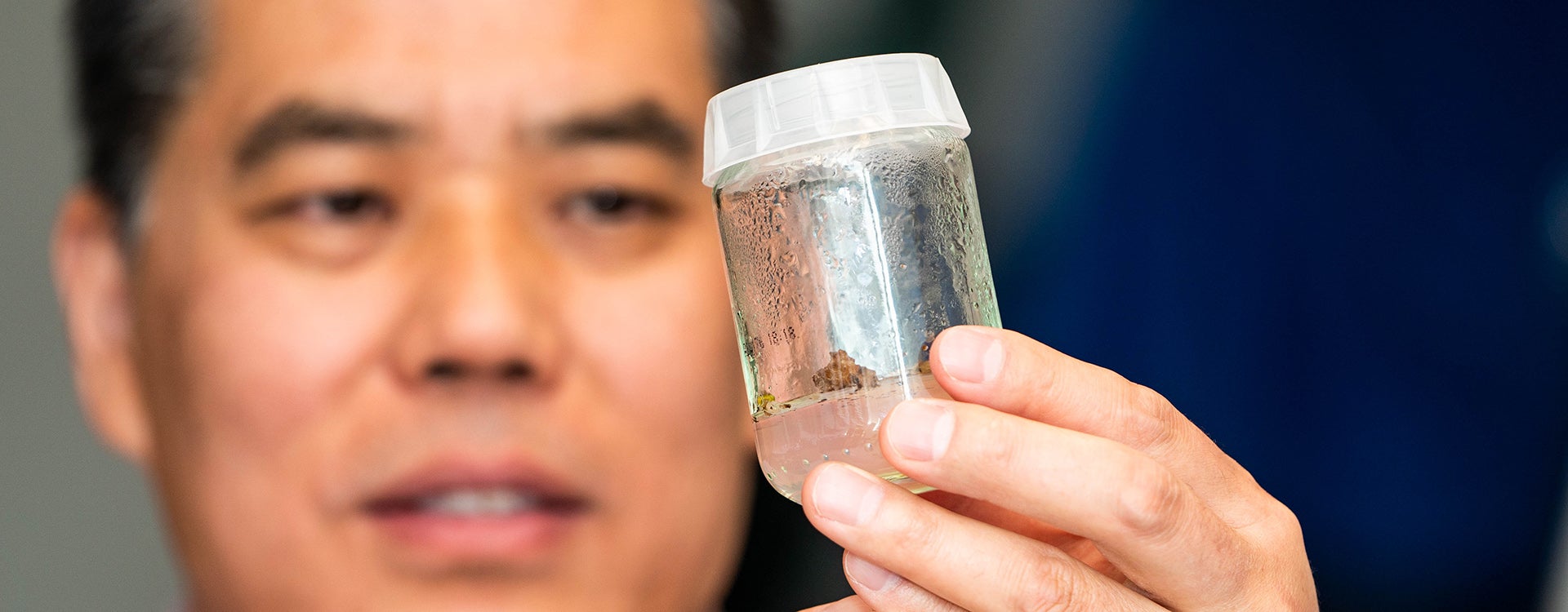

Typha or cattail plants – the tall, reedy plants pictured above at the wetlands project – help remove excess chemicals in the landfill’s drainage. (Photo by Cliff Hollis)

Dr. Janet Sanders, assistant professor in the Department of Technology Systems, is one of the two professors at ECU qualified to teach the course. Sanders said the students must be able to quantify the improvement and clearlyshow what is being measured.

Ryan worked with the Cumberland County Landfill manager to improve the landfill’s efficiency with mandatory testing. The landfill, in accordance with rules set by the Environmental Protection Agency, must test the chemical levels of its four sediment basins, once a month and after heavy rains. Due to the smaller contaminants that may remain in the water run-off, there is a potential environmental danger to wildlife present in stagnant waters and the nearby water source.

According to Ryan, the testing costs about $600 each year per basin, including travel costs for testing done off-site in Wilmington.

Ryan found that growing a wetland within the sediment basin would remove excess chemicals in the drainage. With Typha plant (commonly known as cattails) and grass collected from a nearby wetland environment, she reduced the amount of chemical oxygen demand – the amount of organic compounds in the water to determine organic pollutants – phosphates and some nitrates from the basins.

“We walked to a wetland near the landfill and took some plants to plant them in the basins,” said Ryan.

As a trial run for the project, Ryan said they created a wetland environment within one sediment basin to test her research. Her goal is to have a small wetland planted within all four of the sediment basins by the end of this summer. With the installed wetlands acting as a second filter for the run-off, testing would not have to be performed after every heavy rain, just once a month in accordance with the EPA. The landfill should save approximately $109,000 dollars annually – because of the decreased amounts of testing required – with the changes that Ryan implemented.

Johnson completed his project with Power Mulch, Inc. at the Charlotte Regional Intermodal Facility. His goal was to increase the company’s revenue by streamlining the process used during installation of erosion control socks. The black flexible material is filled with compost to keep soil and clay from running into the waterways near the construction site.

Johnson said he enjoyed seeing techniques from class applied, knowing the project worked and saving the company money.

“I heard about Six-Sigma in the military. We used a lot of the same methodology that I learned at ECU,” said Johnson.

ECU graduate student Robert Johnson streamlined installation processes for erosion control socks. Pictured above, the socks are filled with mulch and installed on a grassbank to prevent soil erosion near a railroad track. Johnson’s project saved Power Mulch of Charlotte close to $2,500 a day. (Contributed photo)

Johnson developed standard operating procedures for the people installing the erosion control socks. Better organization of project materials prevented excess time waste. The changes that Johnson made to the organization of the worksite and the workers increased the amount of erosion control socks installed from 1,530 feet to 2,340 feet per day.

“I was making sure the workers were efficient in the operating procedures and making sure the tools were ready and in the trucks at the site. If someone left their tools, they would have to waste time to go get them and come back,” explained Johnson.

The savings are measured on a daily basis because of the nature of the project. Soil erosion control will not be a constant expense for the company. Since the beginning of the project in January, the average daily savings amounts to $2,427, according to Johnson.

Progress within the Lean Six-Sigma program is measured with different colored belts and only a certified Black Belt can teach the program. Students progress through the certification process similar to martial arts with yellow belt, green belt and black belt. The two ECU graduate students completed the certification program as black belts.

The graduate certification program was completed entirely online, with the exception of the final project presentation, given to the student’s sponsoring company. Though Sanders said the students are not required to inform her of the final presentation, she likes for them to tell her so she can try to be there.

“I feel I have helped give students skills to further contribute to society,” said Sanders.

This fall will begin the third year of the Lean Six-Sigma certificate program at ECU. Currently, 12 students are enrolled in the certificate program. ECU is one of three universities offering this program in the state.