REAL-LIFE ENGINEERING

ECU students develop labor and delivery bed

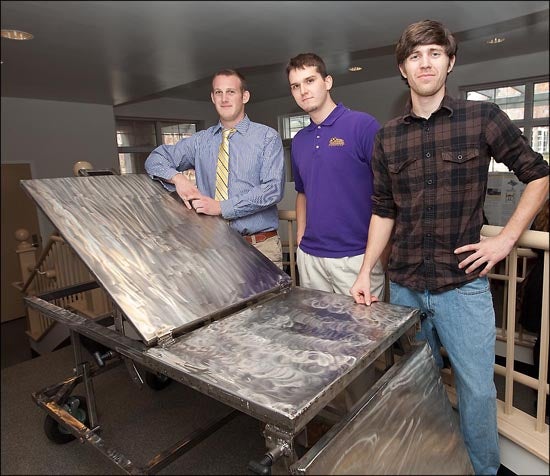

ECU engineering students, left to right, Josh Browder, Andrew Bott and Dustin Rogers developed a labor and delivery bed as part of their capstone project. (Photo by Cliff Hollis)

A group of recent graduates from East Carolina University’s Department of Engineering never considered the equipment required to deliver a baby. A senior capstone project assigned to the four males last January changed that.

Hours of research led to the creation of a labor, delivery and recovery bed unveiled this December – incorporating three essential functions in one mobile apparatus. Capable of running without electricity, their prototype was intended as a model for use in an Afghanistan hospital partnering with the U.S. Centers for Disease Control and Prevention.

The student team was led by Dustin Rogers and included two other students also concentrating in biomedical engineering, Andrew Bott and A.J. Malicdem. A fourth member, Josh Browder, earned a degree focused in mechanical engineering.

Dr. Stephanie George, assistant professor of engineering in the College of Technology and Computer Science, suggested and oversaw the project. George worked with the CDC while earning her doctorate at the Georgia Institute of Technology. When she inquired about potential student capstones, they mentioned the need for such a bed.

“There’s a big push to improve maternal health and fetal health internationally,” she said. “The bed could improve care…and by improving the care perhaps you could reduce the mortality rate.”

She said many women must move from room to room between beginning labor, delivering the baby and recovering after the birth. That can increase the risk of infection or injury to both mother and child.

Their liaison with the CDC provided only a small list of requirements, including that it should function without electricity and be light enough to be lifted by two grown men. The student team expanded on that, choosing to make it somewhat collapsible and adding wheels to aid mobility.

“We wanted to design something that’s going to work in real life,” said Bott. “It was kind of open ended. It could have gone many different directions.”

The design phase went smoothly with the assistance of a computer software program, but actually building the prototype was a greater challenge.

“None of us really had any welding experience or machine shop tool experience,” Rogers said, explaining they got a crash course in use and safety before setting to work. Bott said construction was his favorite phase of the project.

The prototype could be improved, the students agreed. Consultations with nurses and a doctor in ECU’s Brody School of Medicine led them to consider the addition of stirrups or foot rests for the bed. They also think circular instead of square metal tubing would be ideal, as would the use of a lighter metal.

“It seemed like everyone we showed it to was surprised with how much we got done,” Rogers remarked.

“It was real-life engineering work experience,” Bott said.

Dr. Hayden Griffin Jr., chair of the Engineering Department, said all capstone projects match students with local industry or government partners to complete a meaningful project that encompasses all they’ve learned. Still, this one struck him as unique.

“One of the differences with this capstone is that it has a clear benefit to people and their health and well-being,” he wrote in an email.

The department may carry the project forward with another capstone team, George said, who could make the adjustments suggested by the initial team in a more polished prototype and test its use in birth simulations. Students from the College of Nursing and the College of Allied Health Sciences could also get involved, she suggested.

George is expecting her third child in February, and though she wasn’t pregnant when the project began, it seems fitting she should oversee it. Asked if she planned to deliver on the prototype bed, she said she would rather not, but added, “I would trust it to hold my weight.”