PRESERVING PPE

ECU, Vidant team develop process to decontaminate, reuse personal protective equipment

Failure was not an option.

A team from East Carolina University and Vidant Health developed and implemented processes for decontaminating and reusing personal protective equipment (PPE), especially N95 masks.

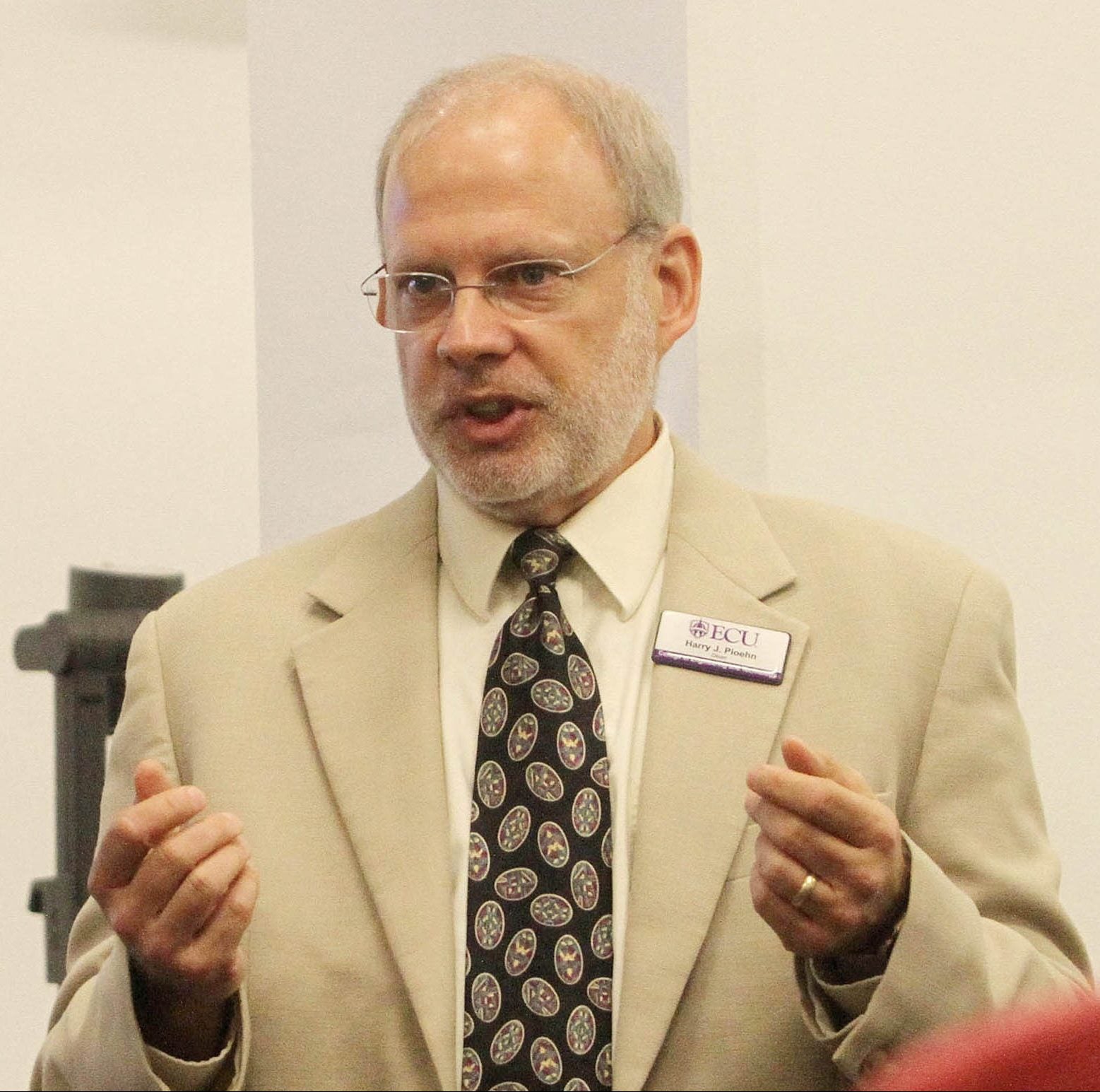

“Failure would put our frontline medical staff at greater risk of COVID-19 illness, decimate their ability to care for our population and certainly cost lives,” said Dr. Harry Ploehn, dean of the College of Engineering and Technology and a member of the team.

The methods will conserve and prolong the usefulness of PPE throughout all Vidant Health locations, ECU Physicians clinics and the Brody School of Medicine in the event that the supply is disrupted.

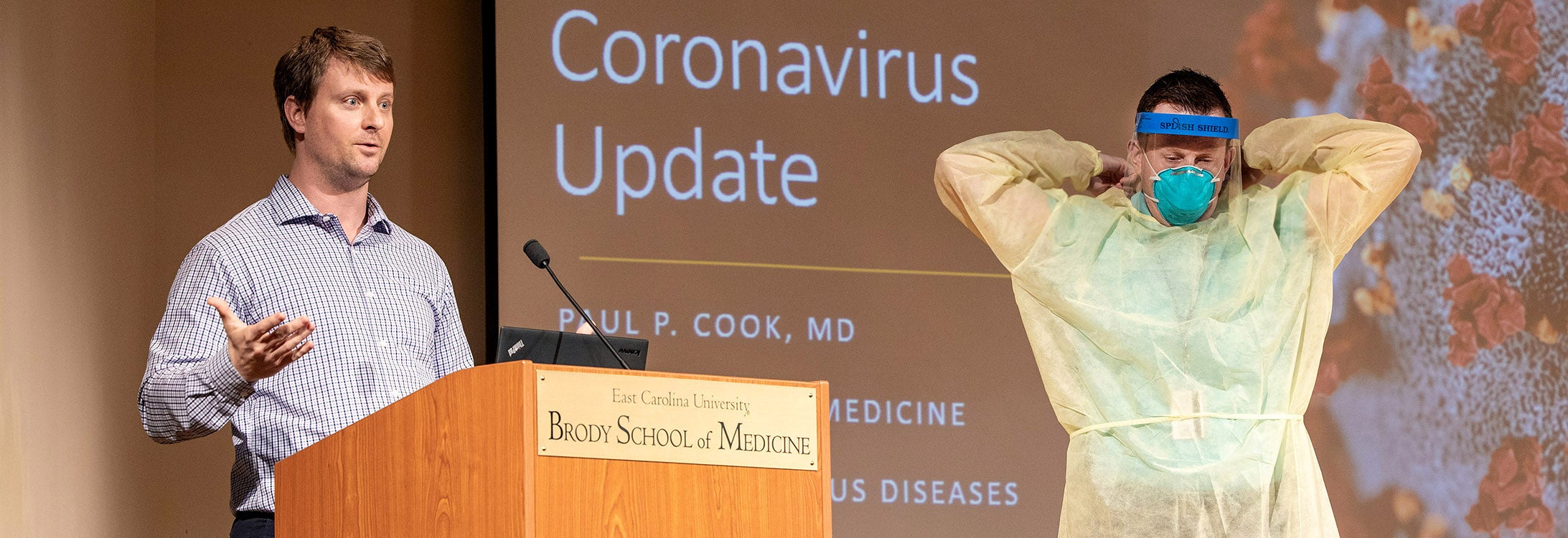

John Baumgartner demonstrates proper PPE use. (Photo by Rhett Butler)

The team had to identify the best methods for virus deactivation and then develop processes that would accomplish virus deactivation with high reliability. They developed two solutions — one using heat and the other using hydrogen peroxide gaseous plasma.

“Our Vidant partners did some early trials to show that heat treatment and peroxide treatment would not degrade the masks,” Ploehn said.

He said the heat treatment deactivates the virus. The process involves heating the masks at 160 degrees Fahrenheit in warming ovens for 45 minutes. With six holding cabinets (ovens) available, hundreds of masks can be processed at one time.

The hydrogen peroxide gaseous plasma process sterilizes the masks, deactivating the coronavirus and essentially making the masks better than when they came out of the original packages, Ploehn said. The process takes about an hour, and Vidant’s Sterrad units can handle 20 to 25 masks at one time.

“In about 10 days, we created, designed and implemented this system,” Ploehn said. “ … We came up with two processes that are fully verified by published scientific work, and we finished it well before the CDC (Centers for Disease Control and Prevention) or FDA (Food and Drug Administration) issued their recommendations. This bought the ECU-Vidant team valuable time to acquire the necessary equipment and supplies, and to set up a centralized decontamination facility to safely sort and decontaminate N95 masks, face shields, gowns and other PPE.”

Dr. Michael Zimmer, senior business consultant and project lead with Vidant Health added: “It was essential we had the key stakeholders involved to establish the PPE reprocessing operation. The science had to be sound in order for our efforts to be effective and safe. Our ECU partners were instrumental in helping us develop the blueprints for our protocols, standard operating procedures and requirements.”

The development of the processes did not come without challenges.

“I think our biggest hurdle was that we were asked to do something that is not supposed to be done — reuse disposable masks — so there was not a lot of literature out there on it,” said Dr. Everett C. Pesci, professor and chair of the Department of Microbiology and Immunology in the Brody School of Medicine.

Dr. Harry Ploehn, dean of the College of Engineering and Technology, said developing the process to decontaminate PPE is crucial to protecting medical workers and the community. (Photo by Ken Buday)

Katy Webb, primary research librarian at Joyner Library, and Jana Schellinger, Laupus research librarian, provided needed documents for the team.

“They found many key scientific publications buried in obscure journals incredibly quickly, helping us make fast progress while freeing us from that normally time-consuming task,” Ploehn said, adding that Brody’s Dr. Juan March also contributed online research.

Others on the team include Brody biological safety officer Chad Spruill; Bob LaGesse, the chief operations executive for ECU Physicians; Griffin Avin, director of facilities maintenance at the health sciences campus; Amanda Lucas, Vidant’s director of quality and sterile processing and 2013 graduate of the ECU Master of Science in nursing program; and Vidant’s Obie Godbey, biomedical manager.

“It could not have been accomplished without such a diverse team from across all ECU divisions, including facilities and finance,” Ploehn said. “This was collegiality and collaboration at its finest, and most enjoyable. We’re in a battle, and we are all now brothers and sisters in arms.”

Zimmer described the effort as a “super think tank across the enterprise with incredible results.” He said the combination of subject matter experts with scholarly inputs and research created the process on an expedited timeline, meaning the two organizations could reuse the masks more quickly.

An accelerated timeline is the reality for health care during times of pandemic, said Brian Floyd, president of Vidant Medical Center.

“As we planned for the pandemic and the impact to our region, we identified key issues that needed innovative solutions,” Floyd said. “I am so proud of our teams as they continue to mount a historic and heroic response. This vital project is an important example of the incredible work happening in the east. The power of collaboration is helping us save lives. At Vidant, we are thankful for the experts at ECU and their willingness to help us serve our region.”

Ploehn said he appreciated the help of the College of Engineering and Technology leadership team that supported the college’s faculty and students while he helped with the project.

“Personally, this has been my proudest accomplishment as an engineer, researcher and administrator,” Ploehn said.

Pesci said the team worked well and produced a good result.

“I also greatly enjoyed working with this team, and I’m proud of what we accomplished in such a short time,” he said. “I think we’ve provided them with very good options to protect our medical providers if or when mask supplies run low.”